Project Demonstrations

Live System Demonstration

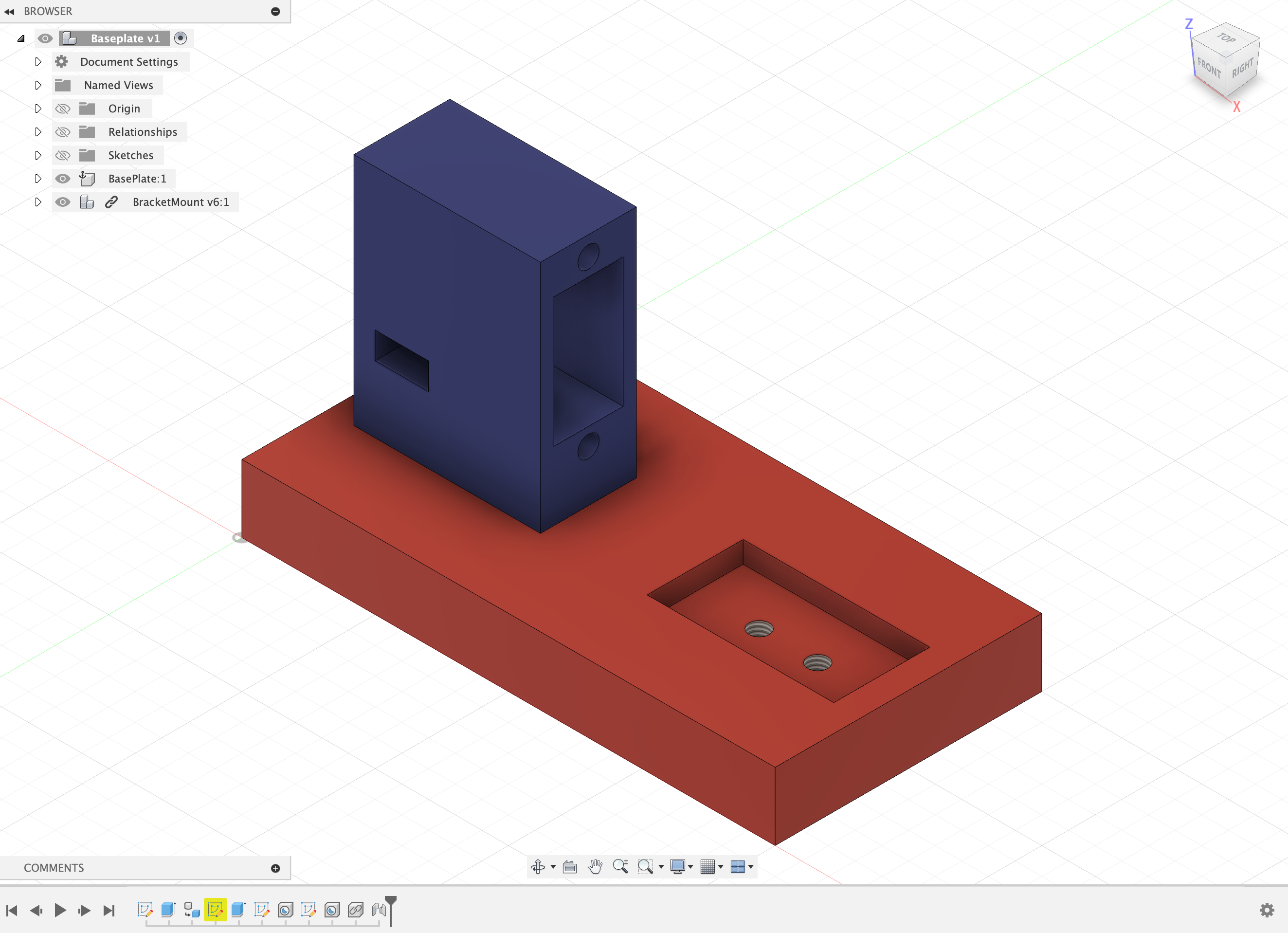

Experience our complete fuel lab testing solution in action. See how the Arduino-controlled robotic system performs automated testing procedures.

Live System Demonstration Videos

Tap to Pay Testing Method

Demonstration of the actual tap to pay fuel testing method in action

Remote Robotic Arm Control

Remote control demonstration showing robotic arm functionalities and precision operations

Key Features Demonstrated: